• 4 min

Pipes Used in Gas Connections

Gas supply systems are a critical part of modern construction infrastructure, ensuring comfort and functionality for residential, commercial, and industrial facilities. One of the most important aspects of designing and installing gas systems is the selection of pipes. This article provides a detailed review of the types of pipes used in gas connections, their technical specifications, advantages, disadvantages, installation methods, safety regulations, and modern innovations in the field.

Requirements for Gas Connection Pipes

The selection of pipes for gas systems must comply with strict standards to ensure safety and efficiency. Below are the main requirements for pipe materials:

1. Mechanical Strength

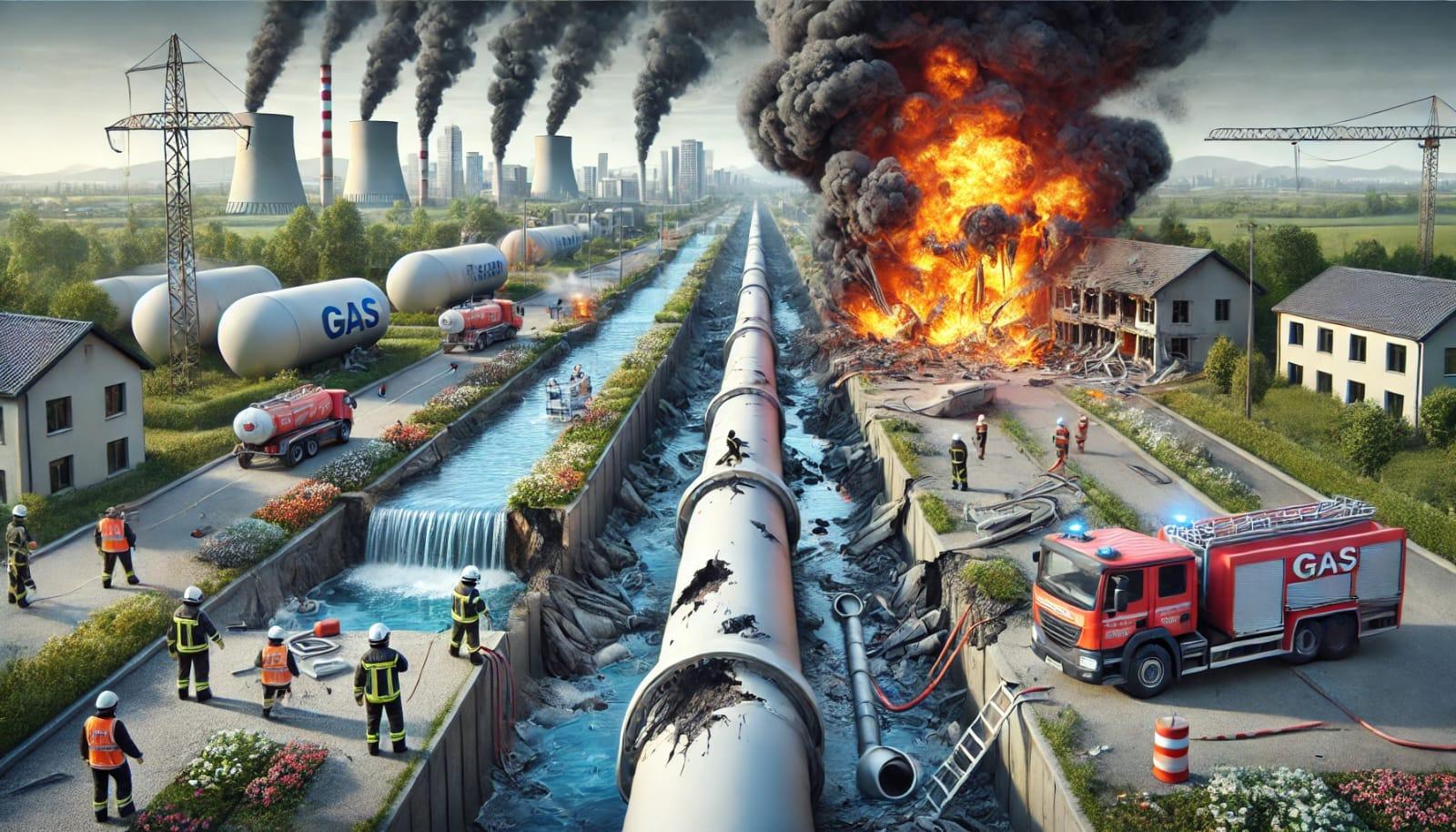

Pipes must withstand high internal pressure and mechanical loads that may occur during operation. This is particularly important for underground networks, which face impacts from soil, transportation, and other factors.

2. Corrosion Resistance

Gas pipelines are constantly exposed to external environments, so the pipe material must be corrosion-resistant to ensure longevity.

3. Airtightness

The main function of gas pipes is to retain gas without leaks. Airtightness depends not only on the material but also on the quality of joints.

4. Resistance to Temperature Changes

Gas pipelines must operate reliably across a wide range of temperatures, especially in countries with seasonal climate changes, such as Ukraine.

5. Certification

Pipes must meet national and international standards such as GOST, EN, or ISO. This confirms their quality and safety.

Types of Pipes for Gas Connections

Here are the main types of pipe materials used in gas supply systems, each with unique advantages and disadvantages that define their application.

1. Metal Pipes

Metal pipes, particularly steel and cast iron, are a traditional choice for gas networks.

-

Advantages:

- High mechanical strength.

- Resistance to high pressure.

- Long service life under proper conditions.

-

Disadvantages:

- Susceptible to corrosion.

- Heavy weight, complicating installation.

- Requires regular maintenance.

Steel pipes are widely used for industrial and main gas pipelines.

2. Polymer Pipes

Polyethylene (PE) pipes are rapidly gaining popularity due to their characteristics.

-

Advantages:

- Lightweight, simplifying transportation and installation.

- Resistant to corrosion and chemical exposure.

- Flexible, allowing them to withstand soil deformations without damage.

-

Disadvantages:

- Unsuitable for above-ground installations due to UV sensitivity.

- Limited resistance to high temperatures.

3. Copper Pipes

Although less common, copper pipes can be an ideal choice in certain situations, particularly for indoor networks.

-

Advantages:

- High corrosion resistance.

- Aesthetic appearance for exposed installations.

-

Disadvantages:

- High cost.

- Susceptible to mechanical damage.

Comparison of Pipe Materials

Below is an analysis of the key characteristics of various pipe materials:

| Characteristic | Steel Pipes | Polyethylene Pipes | Copper Pipes |

|---|---|---|---|

| Strength | High | Medium | High |

| Corrosion Resistance | Low | High | High |

| Cost | Medium | Low | High |

| Ease of Installation | Complicated | Easy | Medium |

| Durability | High | High | High |

Gas Pipe Installation Technologies

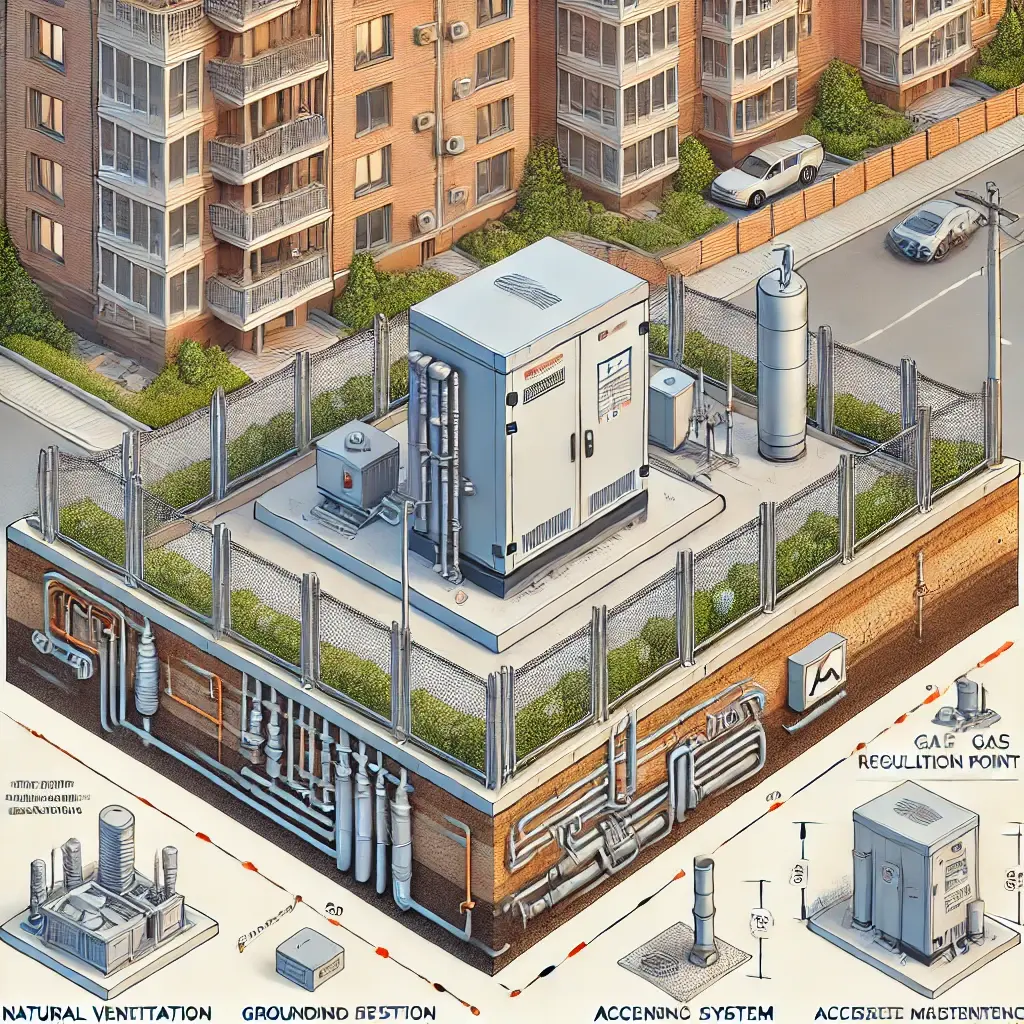

1. Above-Ground Installation

This method is used for industrial and main pipelines. It involves attaching pipes to special supports.

-

Advantages:

- Easy access for maintenance.

- Quick replacement or repair.

-

Disadvantages:

- Aesthetic concerns.

- Increased risk of mechanical damage.

2. Underground Installation

The most common method for urban and private gas pipelines.

-

Advantages:

- Protection from external influences.

- No impact on the visual appearance of the area.

-

Disadvantages:

- Higher installation costs.

- Difficult access for repairs.

Modern Innovations in Pipe Manufacturing

The gas supply industry is evolving, with new materials and technologies making systems more efficient and safer.

1. Composite Pipes

Combining polymers and metals offers high strength and durability.

2. Smart Pipes

Built-in sensors detect gas leaks and monitor the pipeline's condition in real-time.

Why Choose TrioGasBudProjekt LLC?

TrioGasBudProjekt LLC has years of experience in designing and installing gas systems. The advantages of working with the company include:

- Quality and reliability.

- Compliance with all standards.

- Tailored solutions for each project.

- Competitive pricing.

Conclusion

Selecting the right pipes for gas connections is a crucial decision that affects the safety, efficiency, and longevity of the system. It is recommended to work with professionals, such as TrioGasBudProjekt LLC, to ensure the best solution for your project.

FAQ: Frequently Asked Questions

1. Which pipes are suitable for underground gas pipelines?

Polyethylene pipes are the best choice due to their corrosion resistance.

2. Can steel pipes be used for indoor networks?

Yes, but they should be treated for corrosion protection.

3. How to choose pipes for gas supply to a private house?

It is recommended to use polyethylene pipes for underground installation and steel pipes for external setups.

4. How long does gas pipe installation take?

It depends on the scope of work, but typically ranges from a few days to several weeks.

5. Why is pipe certification important?

Certification ensures the pipes meet safety and durability standards.

6. Can gas pipes be installed independently?

No, only certified organizations should perform gas pipeline installations.